We are manufacturers of conical screw mixers from the Czech Republic (Europe). Let us introduce you our production program.

DESCRIPTION OF THE DEVICE

General description of the Vertical Conical screw mixer – type HV

The Conical screw mixer mixing device is designed for mixing of loose and powder mixtures in the food , chemical and pharmaceutical industries, as well as in feed and other industries.

Conical screw mixer

The principle of the mixing device of the Vertical Conical screw mixer type HV

Mixing device – The HV vertical Conical screw mixer operates on a planetary vertical mixing principle when the screw agitator rotates around its own axis and delivers the bulk material from the bottom of the conical vessel upwards. The arm of the agitator, on which the worm stirrer is mounted, rotates about the center axis of the conical vessel, thereby stirring the loose mixture throughout the volume of the conical vessel.

Application of Vertical Conical screw mixer type HV

Vertical Conical screw mixer is used in the production of:

- dried instant semi-finished products, beverages, soups, custards, etc.

- blending of coffee varieties, mixtures for the production of coffee products, cappuccinos, etc.

- mixing of loose materials for the production of bakery and confectionary mixes

- mixing of loose raw materials for the production of tea, spices, grass seeds

- mixing of loose mixtures and semi-products for chemical and pharmaceutical production

- mixing of bulk materials for the production of dietary supplements and proteins

- mixing of agricultural feed supplements

- mixing of loose glass and ceramic materials

- mixing of plastics granules, pulp and dyes

- mixing raw materials for the production of plaster mixtures and wall plasters

- mixing of washing powders, salts, etc.

Accuracy and mixing time

Basic parameters: Mixing device – Conical screw mixer type HV

General mixability, mixing precision 1: 100,000

The net mixing time of one batch ranges from 5 to 25 minutes depending on the type of the raw material

Conical screw mixer type HV is a mixing device that can also be used to mix a slightly viscous mixture consisting of, for example, water and loose raw materials. Such a modified mixing device is used, for example, for the production of sealants and paints. Additionally, it is possible to modify the Conical screw mixer HV-type mixing device by injection nozzle which injects a certain amount of liquid into the stirred bulk mixture. If the mixing cone is adjusted to a double wall or a duplicate, we can use the medium to heat the walls of the mixing vessel and thus the mixing mixture.

Advantage of the mixing device – Vertical Conical screw mixer HV

The advantage of this type of Conical screw mixer HV is, in addition to the precision / quality of blending, the ability to mix even only a third of the total volume of the conical vessel while maintaining the same quality / mixing of the mixture as in the full volume, which is rarely achieved by any other horizontal mixing device.

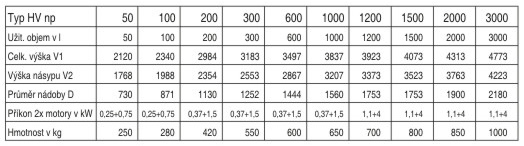

Mixer production line – Conical screw mixer type HV in liters of working volume.

We only use NORD gearboxes to our conical screw mixers.

HV50, HV100, HV200, HV300, HV600, HV 1000, HV1500, HV3000 litres

Material used in the production of Vertical Conical screw mixer

All parts of the machine that come in contact with the blended substances are made of stainless steel class AISI304 or AISI316 etc. These parts are grinded or polished.

The remaining parts of the mixer, e.g. the drive of the mixer, are painted with the food coloring according to the customer’s request.

Location and usage of the mixing device in the technological line.

Mixing device – The vertical Conical screw mixer can stand on its own base or can be located on the surface of the ceiling or any other construction. The raw materials are put to the HV mixer through the lid of the machine. The spraying can be manual or by means of conveyors of different design. The spraying is performed from the bottom by opening a manual or pneumatic shutter. The mixture is poured into containers, sacks or a conveyor of various designs that transmits the blended mixture into another technology, for example a packing machine.

For more information visit www.homogenizatory.cz www.conicalscrewmixer.com

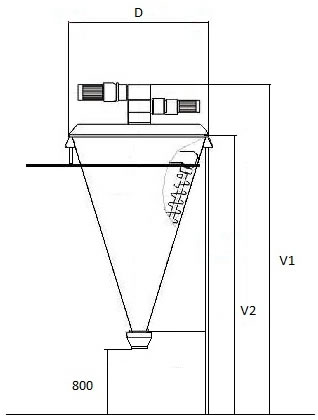

References to the dimensions of each HV type:

Table of dimensional drawing HV Nord

Dimension drawing HV Nord